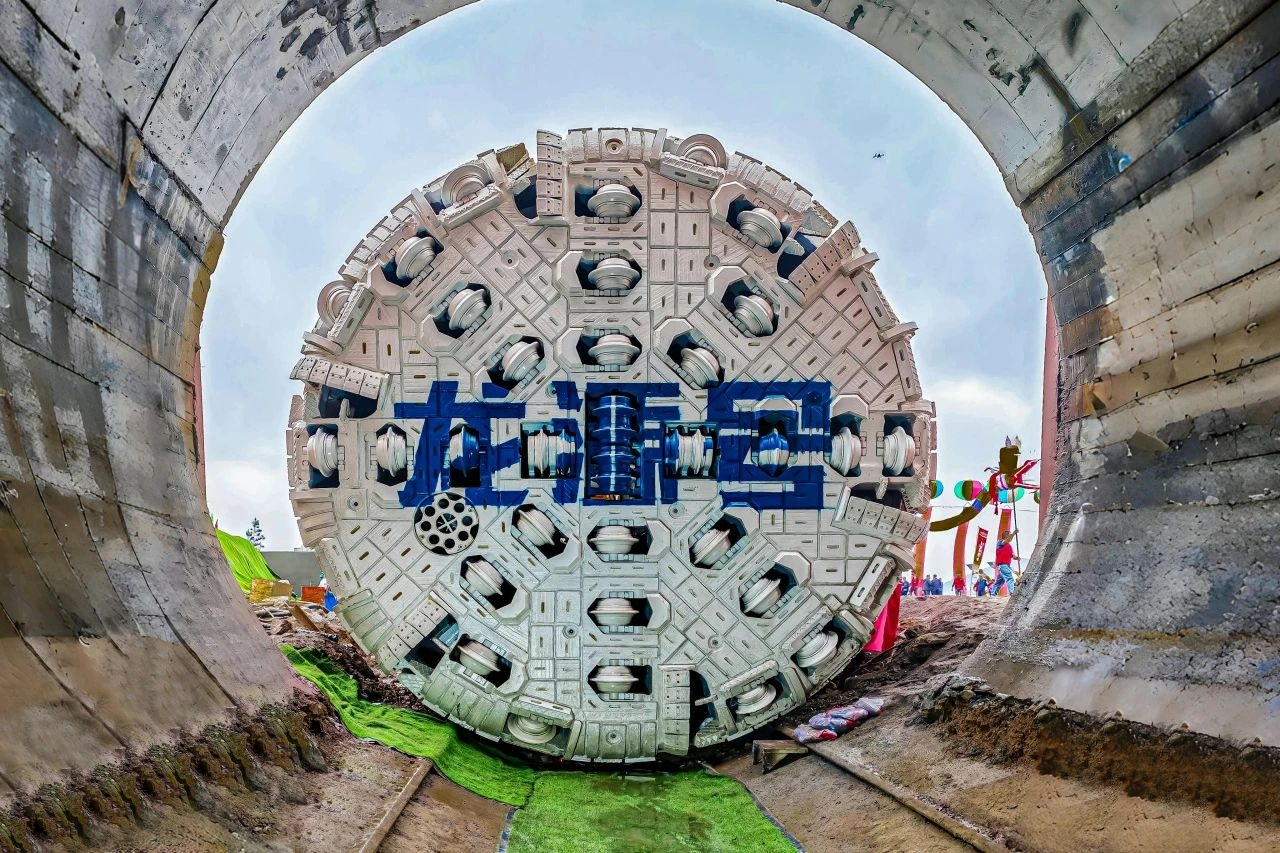

Recently, the world's first tunnel boring machine (TBM) dedicated to lithium mining—“CREC Longyuan” (CREC No. 1103)—jointly developed by China Railway Hi-Tech Industry's China Railway Engineering Equipment Group and Dazhong Mining, successfully completed the 7.3-kilometer transportation corridor excavation for the Hunan Dazhonghe Lithium Project.

The “ CREC Longyuan” TBM was custom-designed for the complex geological conditions of lithium mines, featuring a 6.3-meter excavation diameter, a total machine length of 155 meters, and a weight of about 1,000 tons. It integrates excavation, support, muck removal, and track-laying in one, enabling fully mechanized, synchronized construction. Compared to traditional drill-and-blast methods, it delivers over ten times higher efficiency and significantly enhanced safety, providing strong support for smart mine tunnel construction.

The entire excavation of the transportation corridor in the Hunan Dazhonghe Lithium Project was uphill, with a comprehensive gradient of about 5.7% and a maximum burial depth of 558 meters. The tunnel passed through fractured fault zones and high-pressure water inflow areas. The development team optimized the “CREC Longyuan” TBM according to the site's geological and rock characteristics, equipping it with a steel arch assembler, a rock bolt drilling rig, and horizontal support shoes at the front shield, solving the challenge of long-distance uphill tunneling in deep, complex geological layers.

Since officially starting excavation in May 2024, the “CREC Longyuan” TBM has operated steadily, overcoming numerous challenges including tunneling through faulted zones, water inflows, long-distance hard rock excavation, steep slope material transport, and synchronous track-laying. The project team achieved a maximum daily advance of 57 meters, a single-shift record of 32 meters, a monthly breakthrough of 1,101 meters, and maintained an average of over 1,000 meters of progress per month for three consecutive months.